Compressor Oils

Reliable Lubrication for Industrial Applications

LUBELINE™ supplies premium compressor oils that ensure maximum efficiency, reliability, and protection for industrial air and gas compressors. Whether you operate piston, screw, or Roots-type compressors, choosing the right oil is essential to reduce wear, control heat, prevent deposits, and extend equipment life.

Compressor Types and Lubrication Needs

Piston (Reciprocating) Compressors

- Use pistons and cylinders to compress air in cycles

- Deliver high pressure but are suited to low-to-medium volume operations

- Common in HVAC, refrigeration, and automotive air conditioning

- Require oils with excellent anti-wear protection and high thermal resistance

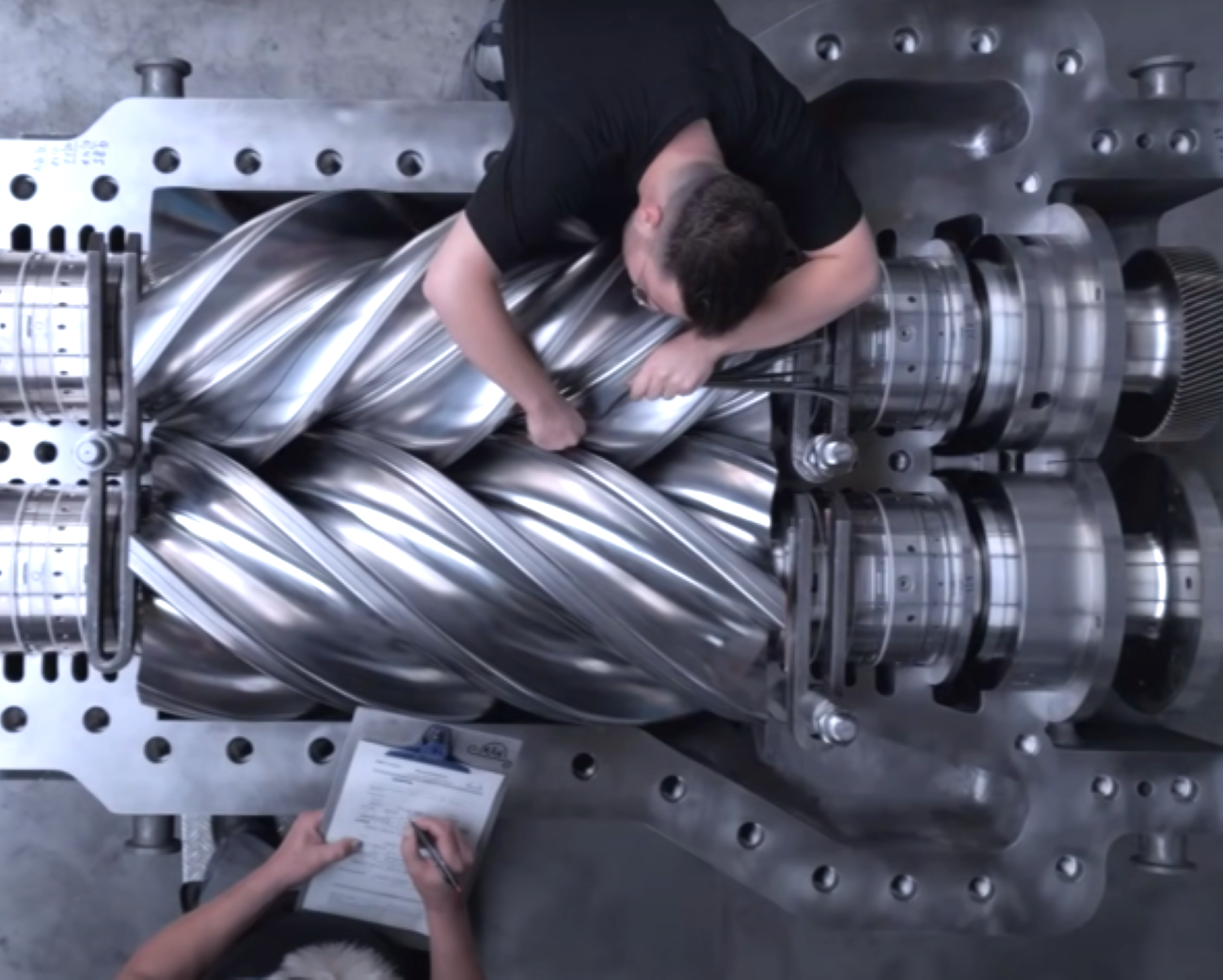

Screw Compressors

- Use helical rotors to provide continuous compressed air

- Ideal for large-scale HVAC, manufacturing, and industrial refrigeration

- Known for reliability, lower vibration, and reduced maintenance needs

- Benefit from oils with oxidation stability and strong film strength under constant load

Roots (Rotary Lobe) Compressors

- Employ two intermeshing lobes to move air efficiently

- Common in pneumatic conveying, wastewater treatment, and process industries

- Require oils that resist foaming and provide consistent lubrication in continuous service

Common Compressor Oil Grades

LUBELINE™ supplies a wide range of compressor oil grades tailored for specific applications:

- ISO VG 32 – Recommended for high-speed rotary screw compressors

- ISO VG 46 – A versatile grade suitable for many screw and piston compressors

- ISO VG 68 – Designed for heavy-duty, high-temperature applications

- Synthetic Compressor Oils – Extended life, improved oxidation resistance, and better protection in extreme conditions

The Role of Compressor Oils in Performance

Industrial compressors operate under high pressure and continuous load, making them highly dependent on specialised lubricants. Quality compressor oils provide:

- Friction reduction for smooth, efficient operation

- Thermal stability & heat control in demanding environments

- Oxidation resistance to prevent sludge and varnish buildup

- Sealing & protection of internal components to extend service life

Using trusted compressor oils minimises downtime, lowers maintenance costs, and ensures clean, reliable performance—critical for industries that run compressors 24/7.